Development is partly financed by the Innovation Fund from the EU Pre-Accession Assistance and from the budget of the Republic of Serbia, the line of the Ministry of Science, Technological Development and Innovation.

PERK – Power Electronics Research Kit

is a state-of-the-art, modular and multifunctional platform for research, development, and testing in power electronics. It facilitates the construction of various power electronics converter configurations, accelerates firmware development, ensures efficient testing, minimizes test setup preparation time, increases safety in the lab, supports continuous integration for power electronics projects and improves the learning process.

GOALS

01

To change the power electronics landscape by significantly shortening the time from concept to realization.

02

To make power electronics more accessible, efficient, and safe for a wider range of users.

03

To help engineers find new solutions in the fields of renewable energy, electric vehicles, and sustainable technologies.

04

To enable faster learning by making it more accessible and affordable to a wide range of users.

PERK Advantages

Time-saving efficiency

cutting-edge technology

Flexibility and customization

Modular design

Wider audience and high reusability

With the highest modularity on the market, PERK offers a solution that enables customers to easily adapt power electronics systems under development to the current project status and to reconfigure them if project requirements change or new testing results show the need for adaptation. Once a project is completed, the same hardware can be reused for another development task.

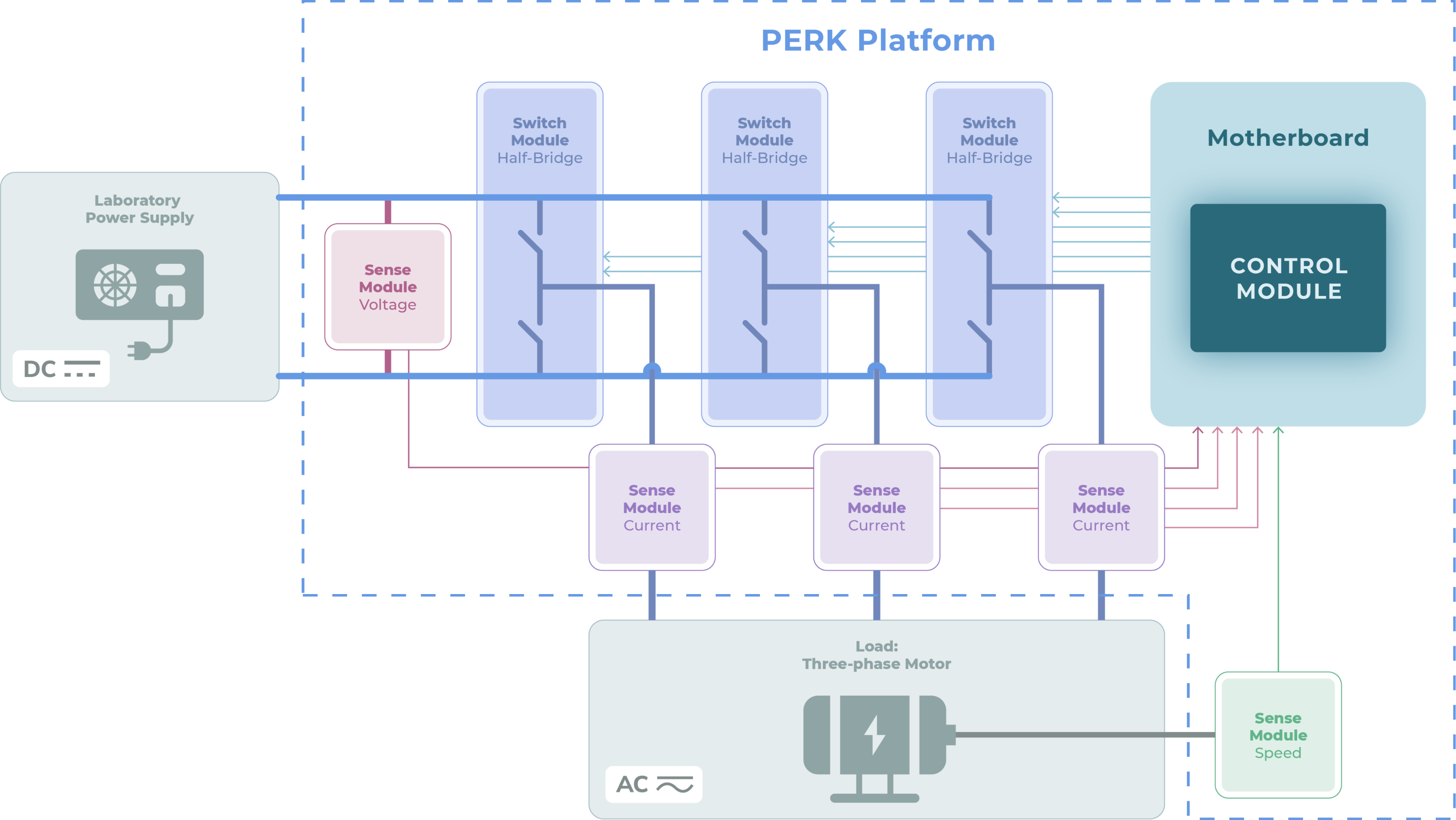

MOTHERBOARD

Central part of the PERK system.

Switch modules

Power semiconductors with drive circuits that are isolated from digital control and can be combined in different power converter topologies.

Control modules

The brain of the system, boards with microcontroller unit (MCU), digital signal processor (DSP) and Field-programmable gate array (FPGA) ICs (integrated circuits) for the execution of control algorithms.

Sense Modules

Sensors for voltage, current, temperature, motor speed, etc., can be freely combined within the power stage due to galvanic isolation and robust signal integrity.

MOTHERBOARD

Central part of the PERK system

Switch modules

Power semiconductors with drive circuits that are isolated from digital control and can be combined in different power converter topologies.

Control modules

The brain of the system, boards with microcontroller unit (MCU), digital signal processor (DSP) and FPGA ICs (Field Programmable Gate Array) for the execution of control algorithms.

Sense Modules

Sensors for voltage, current, temperature, motor speed, etc., which can be freely combined within the power stage thanks to galvanic isolation and robust signal integrity.

PERK Structure of motherboard and various modules

MOTHERBOARDS

Key component of the system that ensures right connection of modules with high level protection, HIL interface, communication interface,DAC monitor and additional features.

01

SWITCH MODULES

Power semiconductors with drive circuits that are isolated from digital control and can be combined in different power converter topologies.

02

SENSE MODULES

Sensors for voltage, current, temperature, motor speed, etc., which can be freely combined within the power stage thanks to galvanic isolation and robust signal integrity.

03

CONTROL MODULE

The brain of the system, boards with microcontroller unit (MCU), digital signal processor (DSP) and FPGA ICs (Field Programmable Gate Array) for the execution of control algorithms.

04

ADDITIONAL MODULES

PERK debugger, suitable for various microcontrollers (Texas Instruments, STMicroelectronics), FPGAs, etc.

EXAMPLE 1

AC motor drive with PERK

The developer uses PERK Switch modules to build an AC-DC converter, while the closed-loop control is based on the measurements of the PERK Sense modules to produce a constant voltage at different current loads. Since this circuit is simpler, the user would probably use only two PERK Switch modules, two or three PERK Sense modules, the same PERK Motherboard as in the previous example, but a different PERK Control module, allowing the use of simpler and cheaper microcontroller.

PERK MODULE USED

- Maximum voltage: 100V

- Maximum current: 80A

- Maximum temperature: 120 degC

- Dimensions: 55mm x 100mm x 15mm

- Cooling options: active, air-forsed cooling (built-in control)

SUPPORT FILES

- Datasheet (link, pdf)

- 3D model (link, step)

- Examples (link)

Contact Us

info@sensendrive.com

Vladetina 1, 11060 Belgrade, Serbia

+381 (63)-758-15-24